Last update November 12, 2023

Overview

In this article you will find out what are stockouts, why are they dangerous for your business, and, most importantly, how you can easily avoid stock-outs. Learn how you can effortlessly improve your stock management and scale your business and brand reputation.

What is a stock-out

Stock-outs, aka out-of-stocks, can be defined as the lack of stock availability of a selling product on sales channels and sellers’ inventory.

Of course, stock-outs of some products are usually physiological while running a business. Indeed, it is completely normal not to always have immediate goods replenishment of best-selling goods, especially during seasonal sales or periods with high sales volumes (Halloween, Black Friday, Christmas, and more).

However, when the demand of buyers is higher than the sellers’ ability to fulfill it, and goods cannot be sold even if the listings are still active on platforms, then stock-outs can impact your business negatively and undermine your reputation as a seller in the eyes of the buyer.

And that is what we can define as the pathological aspect of out-of-stocks, especially when they happen because of oversights, bad inventory management, and human errors.

Why you should avoid stock-outs

What is the problem with stock-outs?

As mentioned above, stock-outs can affect reputation, and can cause you several undesirable problems:

- Missed sales. Usually, people don’t like to wait, so they are more likely to leave your page and find another seller that has everything available and will fulfill the order right away.

- Backordering. Also called overselling. It’s when your items are out of stock, but due to delays in processing, people are still able to purchase them.

- Besides the potential need to issue a refund if you are unable to re-stock, frequent backorders can potentially lead to an eBay suspension.

- Customer service issues. When automation fails, people will write to you and look for an answer. Angry and somehow disappointed.

- Competitors growth. Your loss their gain. Every missed sale due to the lack of product availability is an opportunity for your competitors to increase their sales, grow their reputation, and ensure a better customer experience that may lead to good reviews.

User

How to manage stock-out situations?

When a stock-out happens when a purchase have been already done, it’s necessary to take action promptly:

- Communicate promptly and apologize for the inconvenience.

- Offer suitable alternatives and pre-order options.

- Provide regular updates on restocking progress.

Deal with a such situation can be troublesome becuase can undermine your seller reputation. Therefore, the best way to deal with such situations is avoid them by prioritizing an effective inventory management to prevent stock-outs.

What are the main causes of stockouts?

Human factors

To introduce solutions that can help you avoid and reduce the stock-out frequency, we need to look at what is mainly responsible for them. In this regard, human errors are most common cause of unwanted stock-outs is an oversight or bad inventory management. You or your team simply have forgotten or missed to update the quantities of products that actually had stock in your warehouse. That happens especially for two main reasons:

- Oversights while selling on multiple channels. In this case, multichannel retailers may have forgotten to update product quantities on channels where the product went sold out. That happens more frequently than you think, and often some time passes before you can notice and take action accordingly.

- You followed the scarcity marketing tactic, but you’re not able to always keep up with sales and stock updates. One of the most used techniques while selling online is giving the impression of scarcity to create urgency and push the users to buy. Indeed, indecision sometimes makes customers skip purchases. Clients may wonder whether they can find your products at a cheaper cost elsewhere or whether it could be better to wait for the next sale, etc.

- All these questions prevent sales in the short term. Scarcity, on the other hand, puts customers in a situation that requires them to make up their mind and take action quickly. Using marketing scarcity is a good strategy that can give a boost to your sales, however, if you do not manage the stock carefully, you may have the opposite result and significantly reduce your sales.

Keep reading to find out how to automate inventory and master the scarcity strategies for your business.

Seasonal demand

Sometimes there is high market demand and people can buy your products so fast that you don’t even notice. And this is very good, isn’t it? Cyclically, there are more intense sales periods than others that can increase the probability of a stockout. However, it is not easy to make predictions and figure out in advance which products require restocking. Who wouldn’t be happy when products get sold fast? But if you don’t have a system that keeps track of inventory shortages, you might miss the opportunity to increase sales during these periods of high demand.

Overselling

It could also happen that your products are already out-of-stock, but you didn’t manage to update the quantities on your sales channels. In this case, customers can buy products that are not available anymore. This situation is called overselling and usually happens due to poor inventory management.

Overselling generates dissatisfaction, a bad reputation, and bad reviews, that impact your future sales. Stock-outs in these cases are even worse than human errors and bad forecasting while restocking.

How to prevent stock-outs

Improve inventory management and accuracy

As mentioned above, one of the most common reasons for stock-outs is bad inventory management. Keeping an eye on each sale channel and manually keeping track and aligning stocks across different platforms is troublesome and is not sustainable in the long run. That’s why one of the best ways to prevent stock-outs is to automatize your inventory management system.

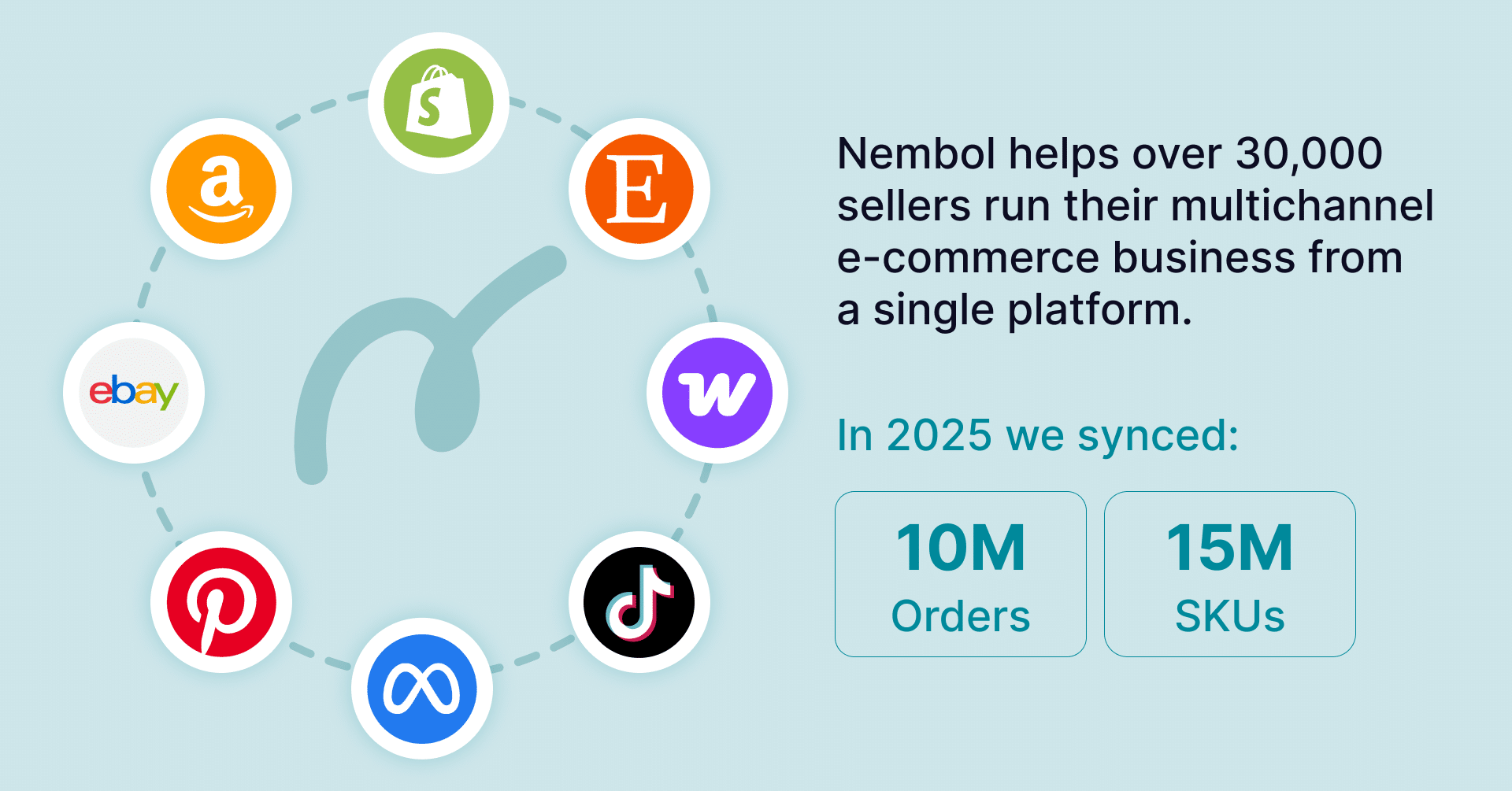

Nembol multichannel inventory sync can help you align in real time the stock every time a sale occurs on one of your connected channels (Shopify, Etsy, eBay, Amazon, WooCommerce, TikTok Shop and more). You don’t need to perform any action because Nembol will work independently, reducing the stocks when appropriate, and avoiding overselling.

Out-of-stock alert

Every time you’ll run out of stock, Nembol will send you an alert and remove the product from the channels. And what if you don’t want to lose your listing history? Easy. Restock your listing quantities via Nembol and reinstate them as soon as your warehouse is replenished.

Try Nembol for free: enjoy a 14-day trial

No credit card required

Set an inventory level

With Nembol you can use the limit stock quantity feature to choose a stock threshold to list and display your products with reduced stock. Every time your products reach availability = 0, they are automatically restocked. In this way, you can “play” with the marketing scarcity strategies and, if you’re an eBay seller, even avoid triggering the eBay selling limit.

Automatic inventory replenishment

As for the inventory level, you can list products with a standard quantity and let Nembol restock them when needed. With this function, you can also manage Etsy limits on quantities and sell more than 999 quantities of products.

Ease your stock management, avoid overselling and unwanted stock-outs, with Nembol inventory sync software.

And bear in mind that on top of hassle-free inventory management, Nembol will offer you a few more easy functions that will help you becoming a more successful online seller, and increase your revenues.

Learn how to sell multichannel: get free education, tips, and inspiration. Start growing your successful multichannel business.

By entering your email address, you accept our Privacy Policy and Terms of Use. Totally free. Unsubscribe at any time.